As you know, shock absorbers are part of the car's suspension system. The operation of the shock absorber requires the movement of liquid within the piston to pass between the two chambers inside the shock absorber cylinder through the oil flow channel inside the piston.

The shock absorber's compression and rebound produces a damping effect to slow down the spring or leaf pulsation.The damping is more or less and how slow or fast it depends on the versatility of the alternating flow and the viscosity properties of the oil are used in the cylinder shock absorber itself.

If the shock absorber set is very damp, the flow of oil through the piston is inconvenient or the oil has a high viscosity. This will stop the spring's pulsation abruptly, but it will cause stiffness or stiffness. The spring suspension can't fully stretch due to vibration because the spring is limited in working distance.

On the other hand, if the oil has a low viscosity, the oil flow can be easily transferred back and forth through the piston. This increases the spring's elongation rate as the spring is freed to operate, thereby absorbing a lot of vibration, resulting in a smoother ride.

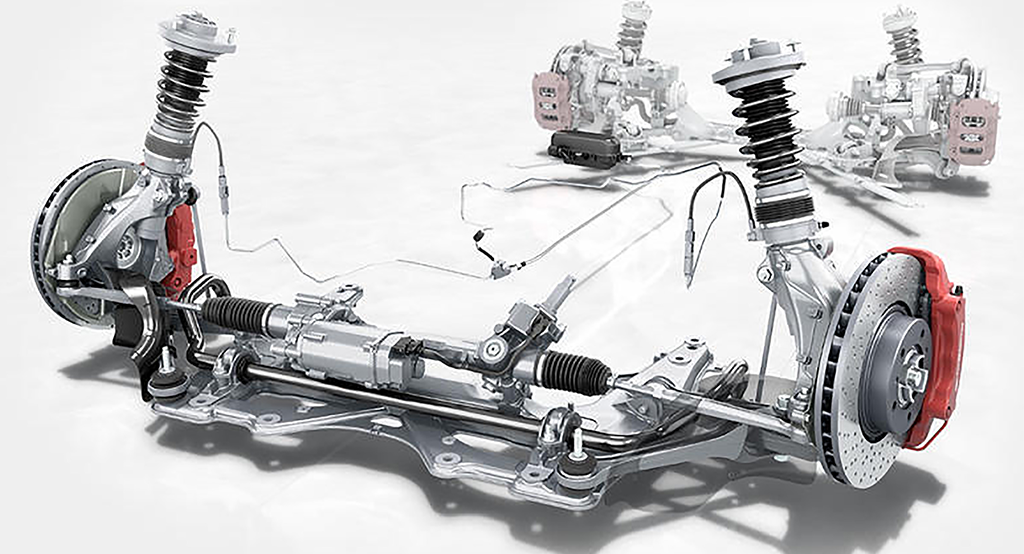

As automotive engineers want to develop a more perfect suspension system, they build on the best of both. This results in an Adaptive Shock Absorber system being born. The principle is to vary the shock absorber damping/expansion rate. This system is used in today's cars (mostly European cars and supercars) as follows.

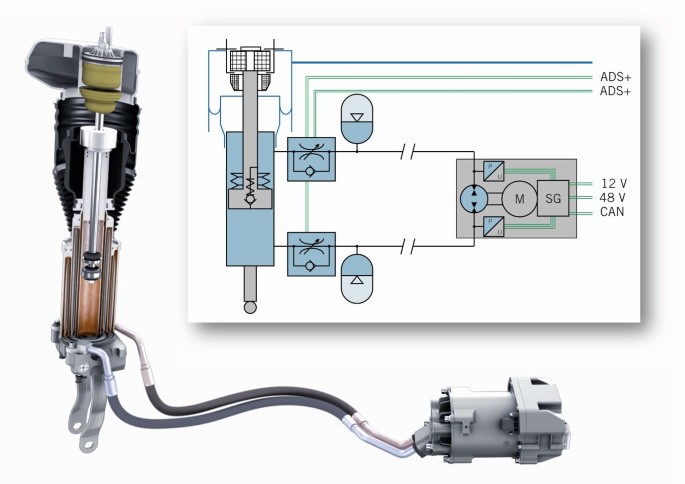

- The electric shock absorber system controls the size of the oil drain valve actuated by a mechanical brain that receives several points data sensor. It is responsible for detecting the stability of the car and measuring the road surface condition in front of the car (only for some models). It increases or decreases the valve size which directly affects the oil flow rate. The system goes by several names by the company that developed it, such as Adaptive Damper System, Active Body Control, Magic Body Control, etc.

- Magnetic shock absorber system is another technology developed by mixing oil and some type of suspension metal that is activated into the oil molecules to become magnetic oil by stimulating the magnetic field, installed inside the shock absorber(Electrical module panel). The name of the system varies according to the company that developed it, such as Magneto rheological fluid (MR fluid), Dynamic Ride Control, Magnetic Ride, etc.

Magnetic oil viscosity properties are adjusted according to the strength of the magnetic field (oil molecule arrangement), which is more responsive than the valve size adjustment.

Therefore, the Adaptive Shock Absorber system, both the electric shock absorber and the magnetic shock absorber, can also adjust the shock absorber damping differently according to the software in each car model and company.

Reference: Mercedes-Benz, Audi AG, Bayerische Motoren Werke AG, LORD Corp EMEA, Automobili Lamborghini S.p.A.